Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 9, 2011 20:29:59 GMT -7

Ok so here I am working on my first 4 gear car. I've just got done trimming the rear wheels down on a lathe to make them fit under a 57 chevy promod body. Now when I put the wheels back on an axle they now will spin freely because they are past the splines on the axle. How do you all work around this. Do you glue the rims to the axle or do what I read elsewhere where somebody created new splines by grabbing the axle with a pair of sharp pliers. I dont like the second option, it leaves too much room for error and the possibility of warping the axle if the face of the pliers are not flat. Any other options??? This is probably going to be a ntra legal ProMod, so it needs to be able to handle a high HP output. A couple of pictures of what I have going on:  Yes the body is sitting funny. I haven't trimmed the stock AW body mounts off the chassis yet. Still have a long way left on this one, I initially started making it a replica of a buddy of mine's turbo promod. But for the sake of simplicity I think I'm just gonna two tone it and call it good.  Just barely clears the rails. Jason |

|

|

|

Post by bondoman2k on Dec 9, 2011 23:16:03 GMT -7

Jason, try finding a 'stock' Tjet rear axle and see how it works. They're shorter than the ones on a 4 gear. That's what I use when I trim the wheels down.  Ron (Bondo)  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 10, 2011 18:39:11 GMT -7

Thank Ron I'll do some hunting for a stock tjet axle. One more question. I did a quick search and didnt find much. Has anybody come up with a decent wheelie bar system for the 4 gear cars. Or do they need them at all since they have a longer wheelbase. I have four of the new AW 4gear cars that are in line to be built into promods. These little things are a whole new world for me.

Jason

|

|

|

|

Post by 440gtx on Dec 10, 2011 22:36:10 GMT -7

I have a problem with using a t-jet axle in a 4-gear chassis. The splines in the middle of the axle that hold the crown gear are so wide that they ride in the chassis creating drag. It will also wear out the axle holes in the chassis. The smooth areas on the axle are completely outside the chassis.  Matt |

|

|

|

Post by nosubfor3 on Dec 11, 2011 6:43:27 GMT -7

I have a problem with using a t-jet axle in a 4-gear chassis. The splines in the middle of the axle that hold the crown gear are so wide that they ride in the chassis creating drag. It will also wear out the axle holes in the chassis. The smooth areas on the axle are completely outside the chassis.  Matt Soooooooooo who has idea's to cure the wobble wheels after the rims are cut down? |

|

|

|

Post by bondoman2k on Dec 11, 2011 10:29:49 GMT -7

Actually Matt, you're right. I just looked closer at the ones I've built and are building and yea, looks like I gotta change the axle.  Guess I don't actually race them often enuff yet to know that could become a big issue. Glad you pointed that out! I probly never woulda seen it till I was either almost done with the car, or after it tears up the chassis! Plus the fact that someone else may have listened to me (I know, a 'RARE' event...LOL) and it ended up ruining THEIR chassis!   Now, the only other thing I know to do is like I did at first, and cut off the outer ends of the axles that come in them, and possibly put a small amount of glue on the end of the axle if needed. You would want to only cut off enuff to still work, but leave at least a small section of the 'splines' on them. I guess you could try to use pliers or something and put your own splines in, but not sure if you'd get enuff splines on the axle to hold it very well doing it that way, I know I personally couldn't do it.  As far as wheelie bars, if you are running any kind of speed, you WILL need them. They are a real PIA to put something on these things. The first one I did, I just drilled into the rear part of the chassis, like in the thread on the how to section on here for putting them on an inline car. BUT, the prob with that is, even after JB welding them to the chassis, you still have to be careful that you don't insert them so far that you rub the gear. You pretty much can only go in the thickness of the plastic, which means the glue won't hold well and they will continually fall out. It may still work for ya that way tho, I do have two cars that I built that way and they appear to be holding fine. Only other thing I can say is look at the thread somewhere (not sure exactly where it is on here) that Jim (Tjetsgrig) posted on the "4 Gear Drag Nova" that he built. You might get the idea from the chassis pics. Basically, a lot of shaving and sanding and a lot of JB weld! If I can get some time in the next day or so, I will try to get some pics of how I did the ones on my Pistonator. They're done just like Jim's. I redid them after seeing how he did it. I originally just drilled and glued them, but they fell out everytime the made a run, even with super glue AND JB weld.  And NoSub, if you are trimming so much wheel that it's wobbling, you trimmed off WAY too much. The backs of these rims are really thick/wide, and you don't have to trim them that far. Some guys have even gone to the extent of sanding some off the outer edge of the rim and repainting the edge black to match the tires. Actually, by painting the outer lip black, it does make the tire look like it has more 'meat'. There is a 'fine line' on how much to remove on these, as you only want to remove enuff to clear the bodies, but not so much that the tires end up riding on the rails of the track. For the record, the tires on these do not have to be all that wide, so you can trim some off them to clear the rails, altho cutting the silicone's is a LOT harder than cutting the 'stock' rubber! Ron (Bondo)  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 11, 2011 15:01:45 GMT -7

It looks like if I clearance the inside of the body a little bit that I will be able to move the wheels out to grab the splines a little. Add a little glue once I'm ready to put them on for the last time and they should be good and solid. Now excuse me I gotta go get the dremel out and do some sanding.

Jason

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 11, 2011 15:48:19 GMT -7

Some cutting, some grinding, and walla the ole chevy is finally starting to sit how a promod should sit.   Looks like I'm gonna have to trim the guild flag/pin down a bit. Its bottoming out in the slot and holding the nose of the chassis up a bit. Jason |

|

|

|

Post by Bananasmoothie1975 on Dec 12, 2011 5:28:54 GMT -7

wait til ya got both front wheels on before ya decide to trim the flag/pin  |

|

|

|

Post by 440gtx on Dec 12, 2011 5:34:51 GMT -7

braids on the pick-up shoes will raise the front a little bit too.

|

|

|

|

Post by pceng on Dec 12, 2011 11:17:41 GMT -7

Hey Jason,

Think alot are having trouble with the tire size and trying to fit it under body. I've gone to a narrower tire. Made things alot easier. Clearing rails and body.

As far as the axels go, now I have to check all the 4g's. Does anybody know of an axel that works.

..............PC

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 12, 2011 20:30:39 GMT -7

PC, once I did some grinding on the inside of the body I was able to space the rear wheels out a little more. Now I can clear the rails no problem. My next step is to get both of the fronts crammed under the body. I've already trimmed them down to the point where they rub the pick up shoes and I cant get them both inside the body. I may go hunting around my box of random parts to see if I can find narrower fronts for it.

If anybody wants to see how much I trimmed off the body let me know I'll snap a pic.

Jason

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 16, 2011 21:06:13 GMT -7

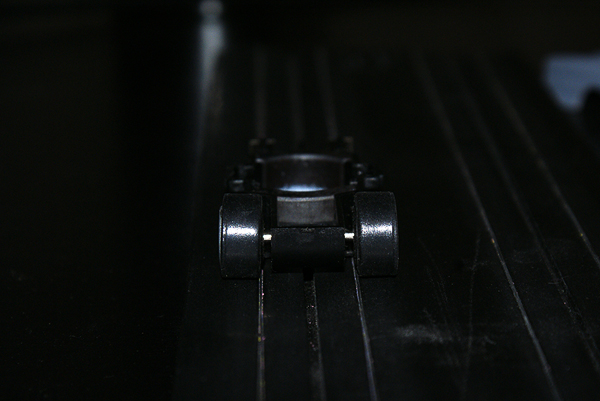

Still scratching my head about the front wheels and tires. I got them and the body ground down enough to be able to tuck them in but now they wont spin. They seem to be up against the pickup shoes and slightly against the body still. I may try a front wheel setup from a stock t jet to see if that will clear everything. It will look kind of funny but if it works it works. On another note all was not lost tonight. I did mange to make some progress and built a set of promod style wheelie bars. They will glue to the chassis at three different points. That should be rigid enough to stand some abuse.   |

|

|

|

Post by pceng on Dec 17, 2011 9:43:26 GMT -7

Jason,

All 4g's I have with body lowered have front wheels and tires from elsewhere. Most of which are from Hot Wheels cars. If you look at cars some have a very narrow front wheel and tire. About the size an o-ring would be. Front axle from AW can be used, be carefull when installing wheels on axles. Lucky to find four of these once, $.99 ea. Haven't found any since.

Think to use stock front wheels and get inside body I, took down wheel from both front and back. Only from back was to much and wheel touches pick-up. Leave a spacer on back of wheel to prevent this. Wheel can be narrowed from front also, tire will also need narrowing. Found the HW's about the same time and never used this set-up but it does work, have one someplace.

..................PC

|

|

|

|

Post by bondoman2k on Dec 17, 2011 10:30:30 GMT -7

For a front axle, on whatever wheels you use, you can also go to your local Hobby Lobby (or hobby shop) and get some 1/16 inch brass rod to use. I do that all the time. Easy to cut too. You may need to ream out the chassis holes and the wheel (1/16 inch drill bit) and put a little glue in the axle hole on the wheel itself, but it's not as 'critical' of a situation as it is on the rear wheels and axles.  Ron (Bondo)  |

|