|

|

Post by SKR on Sept 20, 2014 11:37:15 GMT -7

good Dave, This set up is in my "Blue Hell" FED. At my track it has run a best ET of .39 @ 40mph. I think I'm leaving some on the table with wheel spin since I'm running foams on the rear. I'll be throwing a coat of silicone on them soon to see if I can get the ET down a bit. Note; the 20T idler came from JJ.   |

|

|

|

Post by dave632 on Feb 8, 2015 19:37:18 GMT -7

Thanks for the ideas.

I will get started soon, don't know if I will have it ready in time. Need a reverse rotation armature. or a way to adjust timing, like to try the idea shown in this thread but I may not have the time. Where did you find those tiny screws? I looked on E bay as mentioned but maybe I missed them. |

|

|

|

Post by dave632 on Feb 9, 2015 9:43:10 GMT -7

Thanks for the ideas.

I will get started soon, don't know if I will have it ready in time. Need a reverse rotation armature. or a way to adjust timing, like to try the idea shown in this thread but I may not have the time. Where did you find those tiny screws? I looked on E bay as mentioned but maybe I missed them. Found the screws under small screws and they were incredibly reasonable something like a 1000 for 12 bucks, they even use the Phillips head instead of the dumb slot head which was designed by the cave man back in the stone age. |

|

|

|

Post by SKR on Apr 6, 2016 9:54:56 GMT -7

I'm looking forward to running this class at the Summer Nationals. These are very challenging builds trying to build good power without over powering the drivetrain.

|

|

|

|

Post by AJR on Apr 6, 2016 14:02:26 GMT -7

Sam I'm glad to see you post this. I just told Robert the other day that I was wondering if there was going to be enough interest. This has been one of my favorite and definitely the most challenging class that we run. I have a couple of changes I want/need to make to mine before then. But otherwise they are ready to go as they sit. Remember this?  2014 Summer Nationals NT/F Finalswww.flickr.com/photos/125339246@N04/14613703226/ 2014 Summer Nationals NT/F Finalswww.flickr.com/photos/125339246@N04/14613703226/ |

|

|

|

Post by marz4545 on Apr 6, 2016 15:40:49 GMT -7

That was a pretty rad video, favorite was seeing the tire flying out of the screen.

|

|

|

|

Post by SKR on Aug 22, 2016 10:46:49 GMT -7

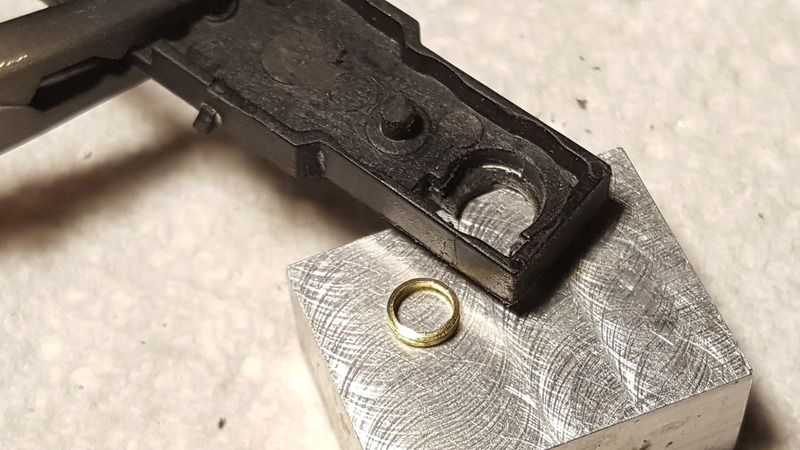

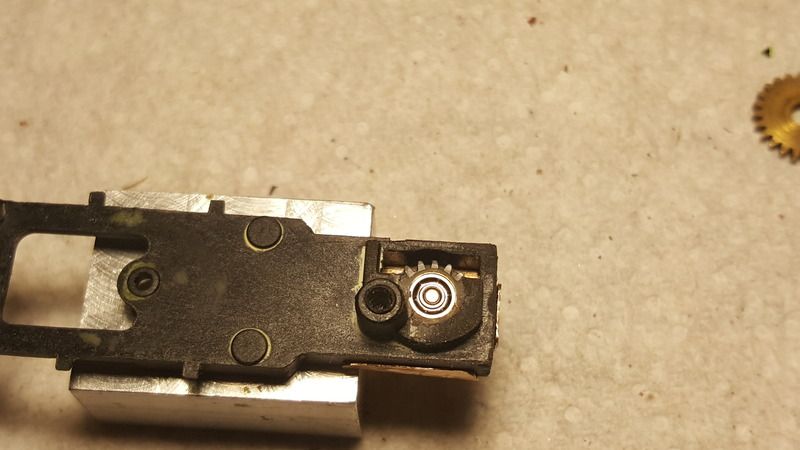

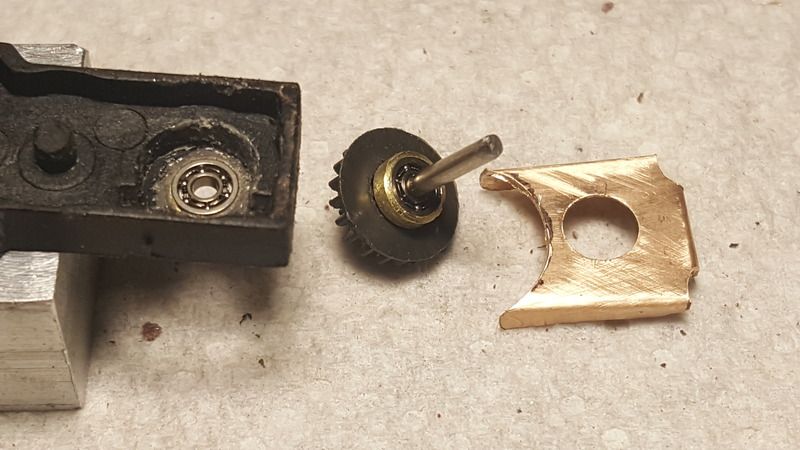

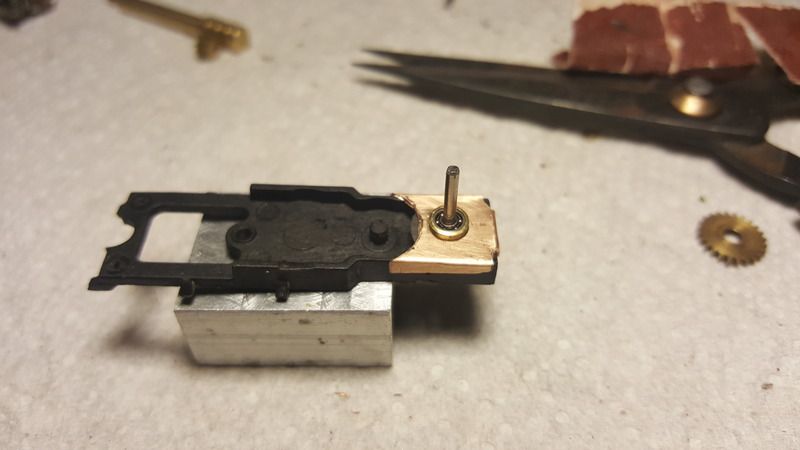

Re-designing the rear gear cluster on my FED.

Opened up the lower gear opening to accept my bearing cup.

After JB Welding, I was able to push my bearing into place.

Next step is to make a cover for the top side to place another cup and bearing.

Dry fit of the new set up. Soon I'll be able to solder the upper cup into place. Shaft will be cut to proper length.

More to come later........ |

|

|

|

Post by sjracer on Jul 19, 2020 7:42:05 GMT -7

From my curent attempt in building an unlimited 4 Gear the rear bushings seem to be the key. I started from the arm and worked my way back. I can find brass gears to fit, without making them. Of course, it does involve some cutting of the top plate. Now how well or how fast the build is.... we'll see later down the road. The rear gear needs to have bushings because it is being manipulated/moved ever so slightly just a few hairs to make the rest of the top plate mesh properly. Drilling a hole with a hand drill helps to make it more precise. This is where the bushings are needed the most because hole that is created when the plastic gear and rivet are removed. Unless you're using the same size gear that you removed it will not line up perfect. Thus, you need two bushings that must be perfectly aligned on the top soldered and cut to size in the brass plated you must build to cover that gets created the and bottom super glued or JB Welded on the bottom. This creates a smooth surface top to bottom for the shaft and should help with wear and tear ( or in case case as close to perfectly aligned as possible). I plan on trying to make a thin brass plate to go on top of the plastic top plate like Sam. To do a small section like JJ I believe screws would get in the way because the last gear is a 14 tooth. However, this would depend on the size of the last 2 gears on the top plate. As it has been established both work.

|

|

|

|

Post by dave632 on Jul 19, 2020 11:27:14 GMT -7

Don't know how much is to be gained over a stock setup with this but anything

that stabilizes the 4G top plate should help.

|

|

|

|

Post by AJR on Jul 19, 2020 14:38:40 GMT -7

From my curent attempt in building an unlimited 4 Gear the rear bushings seem to be the key. I started from the arm and worked my way back. I can find brass gears to fit, without making them. Of course, it does involve some cutting of the top plate. Now how well or how fast the build is.... we'll see later down the road. The rear gear needs to have bushings because it is being manipulated/moved ever so slightly just a few hairs to make the rest of the top plate mesh properly. Drilling a hole with a hand drill helps to make it more precise. This is where the bushings are needed the most because hole that is created when the plastic gear and rivet are removed. Unless you're using the same size gear that you removed it will not line up perfect. Thus, you need two bushings that must be perfectly aligned on the top soldered and cut to size in the brass plated you must build to cover that gets created the and bottom super glued or JB Welded on the bottom. This creates a smooth surface top to bottom for the shaft and should help with wear and tear ( or in case case as close to perfectly aligned as possible). I plan on trying to make a thin brass plate to go on top of the plastic top plate like Sam. To do a small section like JJ I believe screws would get in the way because the last gear is a 14 tooth. However, this would depend on the size of the last 2 gears on the top plate. As it has been established both work. |

|

|

|

Post by sjracer on Jul 19, 2020 15:49:49 GMT -7

Dave, in the evolution of this class many felt that the plastic gears don't and can't hold up. I don't know personally as I got fustrated, perhaps even intimidated by the ease ohers seemed to be able to build them, in the past and gave up. If you're able to make them hold up and eliminate the headache of finding diffrent gears please share. As I stated I've attempted to reach out to any and all who previously built 4 gear unlimiteds. In no way am I alleging that I am an authority on this topic.

|

|

|

|

Post by dave632 on Jul 19, 2020 16:22:19 GMT -7

My chassis has held up for 1 pass so far, not counting the early weak runs. I am running narrow rear tires and the traction magnets are

pretty far off the track to limit traction. I run the rear gear as tight as I can with 0 clearance. How long

it will last I don't know. The 60' time was over .1 which is pretty slow for what it has in it and a car that hit over 30 MPH, but it is necessary to be able to run it

with plastic gears. As a reference a 30 MPH Inline Pro Mod 2.5 will hit the 60'markin the .05-.06 range which is quite a difference.

|

|

|

|

Post by AJR on Jul 19, 2020 18:28:59 GMT -7

My chassis has held up for 1 pass so far, not counting the early weak runs. I am running narrow rear tires and the traction magnets are pretty far off the track to limit traction. I run the rear gear as tight as I can with 0 clearance. How long it will last I don't know. The 60' time was over .1 which is pretty slow for what it has in it and a car that hit over 30 MPH, but it is necessary to be able to run it with plastic gears. As a reference a 30 MPH Inline Pro Mod 2.5 will hit the 60'markin the .05-.06 range which is quite a difference. I would be more interested in knowing what your 3 gear Unlimiteds or Super Comps are running at 60' rather than an Inline SC. Apples to apples.....or at least closer to that. The Inlines just outclass the pancakes. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 19, 2020 19:18:37 GMT -7

this is getting interesting.

keep the ideas AND pics coming!

LOL

|

|

|

|

Post by dave632 on Jul 20, 2020 12:49:51 GMT -7

I will get you some 3G times. The cluster in those seems to be able to handle up to about a mid .4 ET on my track.

I don't remember the 60' times, I will run some of them and see what they can do. The 4G could do better with bigger

tires and traction magnets but then the gears will go up in smoke.

|

|