|

|

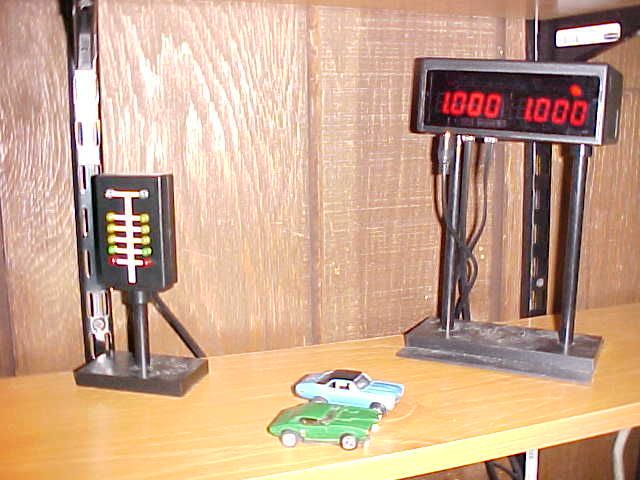

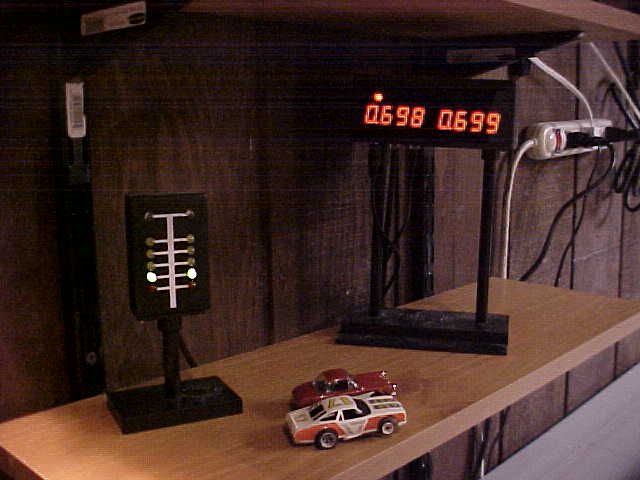

Post by dave632 on Jul 2, 2014 16:52:08 GMT -7

Here are photos of some close races on my track. Side by side runs where only the optics can tell who won. In some cases the reaction time of the car determined the winner as power is put to both lanes at the same time.

|

|

|

|

Post by pceng on Jul 2, 2014 20:55:05 GMT -7

I dig the old t-jet bodies........ haven't seen one in a while.........times are looking better every post....... ......the yellow Camaro takes me back...

................ Peter

|

|

|

|

Post by dave632 on Jul 3, 2014 7:19:03 GMT -7

I sold most of the old T jet and AFX bodies I had. Some I guess were popular with collectors and they sold for big bucks. I still have about a 100 of the old cars, some of which I have had for 50 years, with a few newer ones thrown in. One sold for 175 and another a super II sold for 250. The little yellow Camaro is like a full size 67 I had long ago. It was black with the SS stripe being white. I of course modified the 350 c.i. engine it came with. Times are gradually going down as I experiment with these cars which is half the fun. I have had to add weight to the front of the older T Jets and non magnatraction AFX cars to stop the wheelies which really kill the ETs. I have to look and see where wheelie bars are allowed and do some experiments with them. I picked up about a .1 in ET on some of those cars with nose weights.

|

|

|

|

Post by pceng on Jul 3, 2014 11:08:05 GMT -7

W/bars are allowed on most cars except stock type stuff....... have to also consider voltage....... coming races will be higher end voltages we run......... after that stock and n/ps are coming up , think at 13v..... not sure about n/ps....... think w/bars are allowed for n/ps.......... best to check

|

|

|

|

Post by pceng on Sept 13, 2014 18:24:30 GMT -7

Hey Dave,

4 flat is a good # ........... make top 5 qualifiers easy this year......... next year ? Plan on making mine faster.... Probably everyone else. What kind of chassis are you using , some kind of G ?

...... Peter

Did not want to walk all over thread - - -

|

|

|

|

Post by dave632 on Sept 13, 2014 20:40:55 GMT -7

The fastest so far is a BSRT chassis. I have some other chassis on order such as a Wizzard, etc. and will be comparing which are the best. I have been learning new tricks as I go. Sometimes I have made them go slower with what looked like it should have made them quicker. One car ran great with a new 3 ohm armature at first, then it slowed drastically. Seems to be overheating the brush springs???

My old days of test and tuning the full size cars has trickled down the small scale. I averted many a failure by running my drag cars on T&T nights to see what was and was not working.

Never could come near getting all the power I could make to the ground. Had 3 stages of nitrous on the Beretta and could barely use one of them with about a 250 shot. There was at least another 750 on tap but the chassis could not handle it. Car would always start to lose it when the front wheels touched down at about the 40' mark. I was told the rear housing needed strengthening.

|

|

|

|

Post by pceng on Sept 13, 2014 22:16:12 GMT -7

Dave, sounds like something with brush tubes overheating. Did the springs get soft on you ? If everything spins free & arm is timed right............ brushes could be loose. If it does not spin easy brushes could be tight............. I'm guessing, chassis type & if tubes are adjustable would help narrow the guessing. Why do you say springs overheat ? Are tubes hot ?

........ Peter

Two more questions - were the brushes new........ and how many passes before this began ?

|

|

|

|

Post by pceng on Sept 13, 2014 23:59:59 GMT -7

This is keeping me up....... loose brushes & adjustable is easy fix....... if stock or non-adjustable - could be flash inside batrel impeding spring or just build up of brush crud , dust & oil doing same. Either can result in no brush pressure. But either is cureable. Check your brush movment in barrels. Best if out of car. Holding barrels upright depress brush into tube the let out slowly. If it does not come almost all of the way out of the tube something is binding inside.

If the brushes move ok could be to much pressure. A screw can be backed out or brush shortend. Try brushes about a 1/3 shorter than new if stock barrel. Should have thought about this before.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 14, 2014 2:11:30 GMT -7

low ohm arms with powerful magnets build a lot of heat quickly.

roundy-round guys use heat sinks anywhere they can possibly install them to wick heat from the brush barrels.

BSRT and Wizzard and probably SlotTech have heat sink "screws" to replace the hex screws for most threaded/adjustable brush barrels.

some drag racers living on the heat, explosive edge use compressed gas from stuff like "keyboard cleaner air" to "freeze" the arm just before a pass to fight the heat.

use the can upside down for best results.

in BSRT motor set ups, there is no adjustability or brush tube, so no place to put heat sink that would directly drain the heat causing brush springs to collapse.

those are the chassis the EXTREME racing guys (DRHOE) prefer and have taught me how to build.

so refrigerant is necessary.

how about .182 ET in 15' 7" at around 100 MPH using 28 volts?

I did that around 5 or more years ago with a G3 chassis and BSRT SPUD arm with Neo motormagnets.

Slugger and Steve Geary developed that set up and Slugger perfected it. but I super tuned it and set that ET as a record briefly.

they are down in the .17s now and have heard of high .16s

so, yes, heat is one of the biggest problems and will also KILL NEO magnets quickly too.

hope this has been some help with your program

|

|

|

|

Post by dave632 on Sept 14, 2014 8:17:45 GMT -7

Thanks for the tips guys, I will check out the brush tubes. It is not that wild an armature, about 3.0 ohms. There does not seem to be any unusual drag in the drive train. The brushes and springs were new but I replaced them with new ones again. Performance came back somewhat but not to where it had been. Heat sinks on the brush tubes sound like a good idea, does anyone make such an item? I am now looking for adjustable brush tubes.

Sub .2 times are amazing. How that much power can be put to the ground is even more amazing. The car I ran the fastest time with does spin the tires early in the run and the cleaner I get the track the quicker it is. It has strong traction magnets too. How is an HO sized racer going near 100 stopped?

Getting the power to the ground was my biggest problem in full size racing.

|

|

|

|

Post by pceng on Sept 14, 2014 10:35:38 GMT -7

Dave, if springs are stock...... shorten brushes. Sinks should not be necessary for a 3ohm drag car. Built road cars a few years back with neo's and polys used.sinks....... Brushes could be no more than 1/2 original size without heat being problem. Ttied different spring guages, but only thing to work was shorter brushes. Got so that now I shorten brushes as soon as I get them....... so they are good to.go when needed.

Threaded barrels are great, definitely the way to go. Stock barrels can be drilled & tapped. Bit & tap will do alot of barrels for the price of a few barrels (threaded).

You mentioned tire spin....... if track and tires are clean , may be type of tire that is problem. Think I saw sili-foams in pic........ may be to hard. Most if not all of these are made for different applications or types of racing. Harder compounds for faster cars. Tires made for Super Stock classes work best for 3ohm/ceramic mag, IMO. BUT, selection of tires color is not available. You are pretty much bound by what color tires are available. Unless your only going for looks..... if performance counts paint body's to match because tires won't be black.

......... Peter

|

|

|

|

Post by dave632 on Sept 14, 2014 13:27:43 GMT -7

Thanks, Peter.

I will try the shorter brushes until I can get some threaded tubes.

|

|