Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 17, 2016 9:35:57 GMT -7

I cannot tell how long your timed/powered distance is.

where your finish line is?

you will need at least 6' of shut down to stop the cars.

I recommend 1/4" thick by 1" wide steel strips to replace the track in the shut down.

cars with traction magnets will slow down quickly with that set up.

you can also shunt the strips to create "dynamic braking" or even provide a low power (7 volts ... used 9 volt batteries) REVERSE POLARITY current in the shut down rails.

what is the total length of space you have for the entire drag strip?

how far from start line to finish line for the timing system?

I have built a number of 1/64 drag strips using everything from Aurora O gauge track to professional routed tracks and many different brands of timing systems.

I would like to make positive suggestions since I cannot be there to help personally.

I also have built a couple 1/24 drag strips and was fortunate enough to be included in a store that had my 1/24 scale 1/4 mile on a wall and plenty of local interest. that was quite a few years ago.

you have a top quality timing system so take good care of it.

make sure you put circuit breakers or fuses on the track power to prevent catastrophic failure when a car somehow bridges the rails and causes a short/shunt.

the questions is no IF it will happen, but when!!!

|

|

|

|

Post by theslotcarspot on Sept 18, 2016 11:14:37 GMT -7

Thank You for the information, The drag strip is MaxTrax Eighth Mile it overall it is about 18'long with 84" or so of shut down and 10'3/4" under power. For power the place I got it from was running HP Computer Power Supplies so not sure what kind of power I'm getting. I hope to change to variable power supplies in future.

|

|

|

|

Post by dave632 on Sept 18, 2016 13:39:26 GMT -7

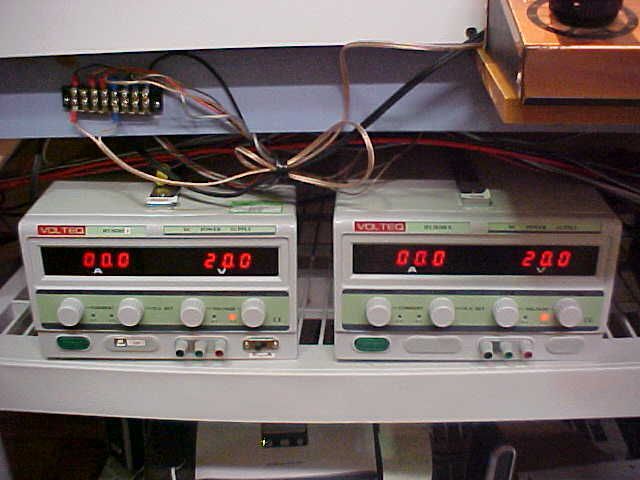

Looks like it is coming along nicely. Al's suggestion for some kind of inline fuse or fast acting circuit breaker is a good idea. The power supplies I have include constant current and short circuit protection so I don't need any. A 0-30V adjustable power supply of at least 10 amps is recommended when circumstances permit and it is better to have one for each lane. I personally use 2 0-30V 30 amp supplies which makes the high draw cars really fly.  |

|

|

|

Post by theslotcarspot on Sept 19, 2016 16:22:51 GMT -7

Thanks, I do like the idea of the adjustable power supplies but will need to wait until I see how the 1/24 Drag Strip which will sit under this one sits as I more than likely will need to change drivers panel area, Also I'm a bit confused on where the trackmate computer should be, is typically away from the track and a race director controls the races. It is hard to tell from looking around how people run things. I will have 5 tracks running Trackmate when done, My idea was to have central station with computers setup up too run races from.

|

|

|

|

Post by dave632 on Sept 20, 2016 7:55:42 GMT -7

That should be an interesting setup. As you can see from this picture the Trakmate system can give you readouts for multiple spots on the track which helps when tuning the cars. This is a 19" diagonal screen shown here. I would think a bigger one would be nice for a commercial setup.  Driver stations need not be to complicated, all I use is a button connected to a relay, for handling high amp draw cars. I used 3 #10 wire hookups, start, middle, end to feed power to the track. This setup gives no power drop off going down the track. |

|

|

|

Post by theslotcarspot on Sept 23, 2016 13:42:49 GMT -7

Anyone in the Houston Area interested in getting something going at our location in Cypress, TX.....

|

|

|

|

Post by theslotcarspot on Sept 28, 2016 14:26:38 GMT -7

Racing tonight on 1/32 Scale Track.. So if any local HO guys want to come out please feel free to...Atomic Hobby Shop The Slot Car Spot 13529 Skinner Rd Suite E Cypress, TX 77429

|

|