HWP

Super Stock

Posts: 12

|

Post by HWP on May 10, 2020 14:11:57 GMT -7

Let me know how it goes Dave... I'm really curious to figure out why that one out of hundreds sold has been so problematic. Could just be a lemon I suppose. The Cobra in that drag race video didn't have magnets attached when I first ran her, and she behaved much like the real car... I could practically do donuts with it. But still rarely de-slotted. I added neo magnets similar to the one in your picture, and it is an absolute rocket on all our tracks, including AFX, Tyco, and even 1/32 Scalextric (I make adapter guidepins to run my braided chassis on them). Quick as mine is, I don't need wheelie bars to keep it in the groove.

I'm really thinking its the braids... the larger rear diameter tires shouldn't have much influence either way on it. Let me know if I can be of any help.

- Jim

|

|

|

|

Post by dave632 on May 10, 2020 14:36:13 GMT -7

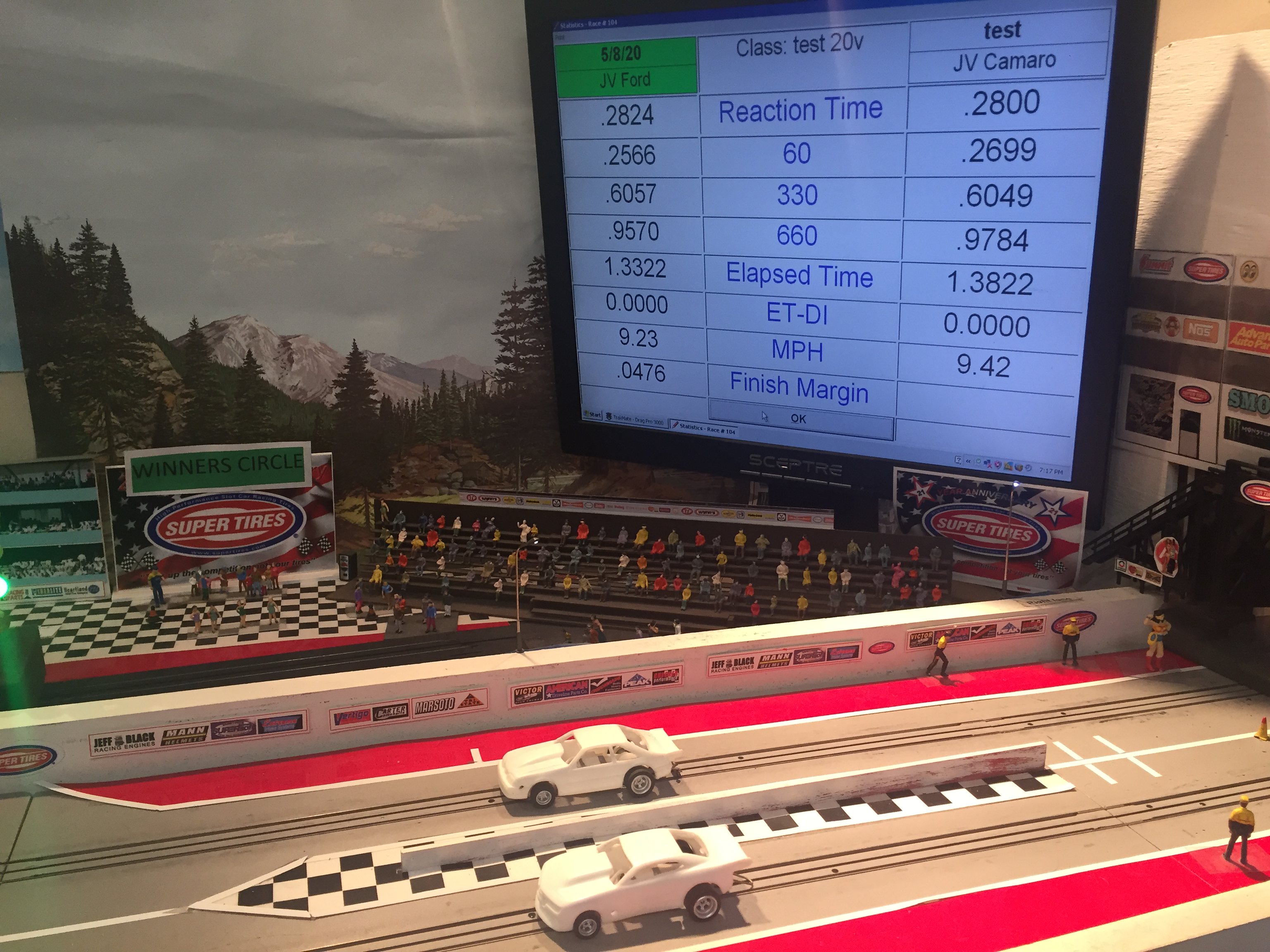

Thanks for your help, and Al's, in solving this problem. Took the stiff braid off and installed my own braid. That braid was the stiffest I have ever seen and I have been using braid for a long time, don't know where it came from as I did not build this chassis. This SOLVED the problem. Runs like a normal inline chassis now, even took the wheelie bars off with no ill effect. Note the difference in ET and MPH. Picked up 5 MPH and a chunk of ET. The Camaro has Super tires on it which accounts for the better ET.  Before Before

After soft braid After soft braid |

|

HWP

Super Stock

Posts: 12

|

Post by HWP on May 10, 2020 16:48:13 GMT -7

Really glad to hear it! Curious to know what voltage you're running at. Performance will obviously vary wildly depending on the specific motor used. And this was one of Dave W's earlier builds. But at intermediate voltage, my Cobra beats the pants off everything including AFX Mega G+ cars running the same class of N20 motor. But at least the main performance issue appears to be solved. Maybe try running it without the magnets in fornt if you still have them on there.

Anytime you have a question or issue with any of my designs, please don't hesitate to reach out to me. Happy to help. And if you have suggestions to improve their performance, I'm all ears. The beauty of 3D printing is that I can quickly iterate designs without the limitations of retooling molds.

Best,

- Jim Miller

HWP Slot Cars

highwingpilot@gmail.com

|

|

|

|

Post by dave632 on May 10, 2020 18:06:18 GMT -7

Thanks for the help and concern.

I run my track at 20 volts, unless a specific race rule changes that, it is 15.5', 1000' scale 1/64, of Max trax with a with a TrackMate DP3000HO timing system. I have 2 30 amp 0-30 volt power supplies so each lane has enough power, both lanes are separately powered.

My suggestion would be larger moveable traction magnets for different size tires and track conditions. The little Neo dots do not give much down force and therefore traction

is suffering. I can generally get a lot of performance out of most chassis. As an example an old AFX pancake chassis with a 6 ohm arm, slip on tires + some of my tricks

will be about .3 quicker than this Camaro and at least 5 MPH faster. The hot inlines like BSRT & Viper will be even quicker and faster. I think I can get this chassis going now

that the awful braid is gone. My guess .6-.7 ETs with trap speeds in the 20-25 range which is comparable with most good production inline chassis after I fool with them. I got one

of the Mega G+ chassis that the guy who sent me these chassis down to .63 ET and 24 MPH where it had been only running times similar to the Camaro. There is a race coming up in 2 weeks

on this site where we run Inline chassis so you can see what some of the guys are getting out of the various chassis. Stock all the way to 50-60 MPH Unlimiteds.

Dave

|

|

HWP

Super Stock

Posts: 12

|

Post by HWP on May 10, 2020 22:13:07 GMT -7

Dave, you've got the non-mag version of the chassis. The flats in front of the rear wheels are designed so you can attach magnets of various sizes and strengths if you choose to. But some builders like running them without magnets.

I make a newer version of the chassis which features fully tunable magnets. It uses grub screws to dial in whatever traction assist you want with 3/16" round magnets. Same fully adjustable wheelbase. I also have a fixed 1.5" wheelbase 4WD chassis which features 4 adjustable traction magnets (front and rear). The chassis all use the same body clip system - with clips for AFX/AW Magnatraction, Mega G/G+, Tyco 440 wide and narrow, MicroScalextric, Lexan pins, etc.

The bare chassis are available through my Shapeways shop. Dave Wonacott does sell them as completely built RTR chassis, and uses the Tyco Pro wipers instead of braids. But many guys build them themselves with standard parts and N20 motors they source themselves. The magnets are available in a range of strengths and thicknesses from KJmagnetics.

There is also a version which holds the 50% longer N30 motor, which I'm told is popular with drag racing for it's higher torque.

Here's a video of the first generation tunable traction chassis. The newest version, the Mk.4, uses a refined clip system that makes installing and swapping the motor a snap. But the overall design is effectively the same.

|

|

|

|

Post by ecbill on May 11, 2020 5:57:10 GMT -7

Dave, you've got the non-mag version of the chassis. The flats in front of the rear wheels are designed so you can attach magnets of various sizes and strengths if you choose to. But some builders like running them without magnets. I make a newer version of the chassis which features fully tunable magnets. It uses grub screws to dial in whatever traction assist you want with 3/16" round magnets. Same fully adjustable wheelbase. I also have a fixed 1.5" wheelbase 4WD chassis which features 4 adjustable traction magnets (front and rear). The chassis all use the same body clip system - with clips for AFX/AW Magnatraction, Mega G/G+, Tyco 440 wide and narrow, MicroScalextric, Lexan pins, etc. The bare chassis are available through my Shapeways shop. Dave Wonacott does sell them as completely built RTR chassis, and uses the Tyco Pro wipers instead of braids. But many guys build them themselves with standard parts and N20 motors they source themselves. The magnets are available in a range of strengths and thicknesses from KJmagnetics. There is also a version which holds the 50% longer N30 motor, which I'm told is popular with drag racing for it's higher torque. Here's a video of the first generation tunable traction chassis. The newest version, the Mk.4, uses a refined clip system that makes installing and swapping the motor a snap. But the overall design is effectively the same. HWP, Would you provide information on where to view and order your chassis? The narrow chassis and adjustability look like they would be handy for making custom cars. Bill |

|

HWP

Super Stock

Posts: 12

|

Post by HWP on May 11, 2020 7:15:59 GMT -7

Hey Bill, I don't want to violate any forum rules - not sure if it's okay to post links to my Shapeways shop. Some other formerly popular forum pages have strict rules against including "competitor"/"advertising" links. I'll have to check this forum's guidelines first. But the whole idea behind the fully adjustable ultra-narrow SL2 chassis is to make all sorts of custom cars possible. From top-fuel dragsters, to open wheel designs - Smart cars to Greyhound buses. I also make a front rail extension that fits the new inline JAG chassis that extends the wheelbase by up to several inches, while looking like a narrow tubular frame. This chassis led to the idea of creating custom chassis-less designs like the vintage 1965 Lotus 33 F1 look-alike, where the body IS the chassis. The motor and parts attach directly into body, allowing for greater design accuracy and freedom. Here's video clip showing the chassis-less design: And a custom "Lotus 33" build of my body by Dave Wonacott:  To give you an idea of the scale achievable, here is the prototype of the F1 body sitting next to a favorite old Tyco S car from my childhood.  Lots of possibilities for the custom builder. Like this delivery wagon with a fully adjustable front end, so it can be fitted whatever "motor" and pipes you like:  Or this old gal... the black fender/frame is the chassis. The coachwork, custom spoked wheels, etc. all attach like an 18-piece plastic model.   I should probably be posting this under a new thread, rather than one devoted to a "Bad Chassis".  Thanks for your interest! - Jim |

|

|

|

Post by AJR on May 11, 2020 7:30:57 GMT -7

Hey Bill, I don't want to violate any forum rules - not sure if it's okay to post links to my Shapeways shop. Some other formerly popular forum pages have strict rules against including "competitor"/"advertising" links. I'll have to check this forum's guidelines first. But the whole idea behind the fully adjustable ultra-narrow SL2 chassis is to make all sorts of custom cars possible. From top-fuel dragsters, to open wheel designs - Smart cars to Greyhound buses. I also make a front rail extension that fits the new inline JAG chassis that extends the wheelbase by up to several inches, while looking like a narrow tubular frame. This chassis led to the idea of creating custom chassis-less designs like the vintage 1965 Lotus 33 F1 look-alike, where the body IS the chassis. The motor and parts attach directly into body, allowing for greater design accuracy and freedom. Here's video clip showing the chassis-less design: Lots of possibilities for the custom builder. Like this delivery wagon with a fully adjustable front end, so it can be fitted whatever "motor" and pipes you like:  Or this old gal... the black fender/frame is the chassis. The coachwork, custom spoked wheels, etc. all attach like an 18-piece plastic model.   I should probably be posting this under a new thread, rather than one devoted to a "Bad Chassis".  Thanks for your interest! - Jim Very cool stuff Jim! FYI.......I have changed the name of the thread to "Chassis setup issues". Much less abrasive. Thank you for sharing! |

|

HWP

Super Stock

Posts: 12

|

Post by HWP on May 11, 2020 7:37:11 GMT -7

Very cool stuff Jim! FYI.......I have changed the name of the thread to "Chassis issues". Much less abrasive. Thank you for sharing! Thanks JJWallace! |

|

|

|

Post by dave632 on May 11, 2020 9:47:56 GMT -7

Thanks for the info. I am sure we can get this chassis going now. Jeff good idea, when I made the post

there were some doubts about what was happening. Fortunately Jim was very helpful.

Dave

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 11, 2020 10:17:25 GMT -7

|

|