|

|

Post by rickvoegelin on Oct 31, 2009 8:26:38 GMT -7

Ah, I think I see my problem now. Not enough adult beverages!

So are you spreading the chassis with a screwdriver or other tool before pushing down the armature/magnet assembly? Do you push straight down on the motor, or work from side to side?

Inquiring minds want to know. Thanks!

Rick V.

|

|

|

|

Post by SKR on Oct 31, 2009 8:43:08 GMT -7

Wen reassembling I pull the chassis apart enough with my fingers for the motor to get started down. I only use the screwdriver when disassembling.

|

|

|

|

Post by rickvoegelin on Oct 31, 2009 14:37:16 GMT -7

Thanks for info on motor installation. I think I am being too tentative with these things. Maybe I should just get out the 5-pound hammer chassis adjustment tool.

Rick V.

|

|

|

|

Post by SKR on Oct 31, 2009 14:48:49 GMT -7

Scale Auto does offers these Final Adjustment Tools   |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 7, 2010 11:50:03 GMT -7

i read your write up and was wondering is that regular auto -motive wire and what gauge? thanks for a great article and for the response in advance. mac

|

|

|

|

Post by 440gtx on Jul 7, 2010 15:47:14 GMT -7

I use the small silver shunt wire that Lucky Bob's sells. It's made by wizzard and the # is E56. It's $1.50 for 18".

|

|

|

|

Post by SKR on Jul 8, 2010 19:25:28 GMT -7

Hey Mac, The stuff I use came from a Electrical surplus store that a friend of mine picked up. You want something that is very flexible so it doesn't interfere with the travel of the pick ups. You can't go wrong with the stuff 440GTX suggested.

Sam

|

|

Dusted

Pro Stock

Big Boyz Toyz

Big Boyz Toyz

Posts: 413

|

Post by Dusted on Jul 12, 2010 9:51:20 GMT -7

|

|

|

|

Post by 440gtx on Jul 13, 2010 15:30:46 GMT -7

That's what we use for the braids on the shoes.

|

|

Dusted

Pro Stock

Big Boyz Toyz

Big Boyz Toyz

Posts: 413

|

Post by Dusted on Jul 14, 2010 8:53:53 GMT -7

That's what we use for the braids on the shoes. Cant it be used to bridge between the connections on the shoes to the plate etc? |

|

|

|

Post by 440gtx on Jul 14, 2010 15:14:09 GMT -7

That's what we use for the braids on the shoes. Cant it be used to bridge between the connections on the shoes to the plate etc? I think the problem with using it for shunt wire is it is too heavy and stiff. On top of that it is designed to absorb solder which would make it even stiffer. Matt |

|

Dusted

Pro Stock

Big Boyz Toyz

Big Boyz Toyz

Posts: 413

|

Post by Dusted on Jul 15, 2010 9:15:12 GMT -7

Cant it be used to bridge between the connections on the shoes to the plate etc? I think the problem with using it for shunt wire is it is too heavy and stiff. On top of that it is designed to absorb solder which would make it even stiffer. Matt OK I didnt think of that Thanks 440 |

|

|

|

Post by reig3 on Nov 20, 2010 20:00:17 GMT -7

Well I was off from work Friday and tore into the build. It wasnt as bad as I thought the puller for the wheels and gears would have made life much easier. The only thing I see is on the GXP body the tires still rub on the inside. I did cut the nipples off the wheels and they are in as far as they can go without hitting the chassis. I guess will take the dremel to the body and try to clearance it.

Awesome instructions Sam.

Bob

|

|

|

|

Post by SKR on Nov 21, 2010 14:00:18 GMT -7

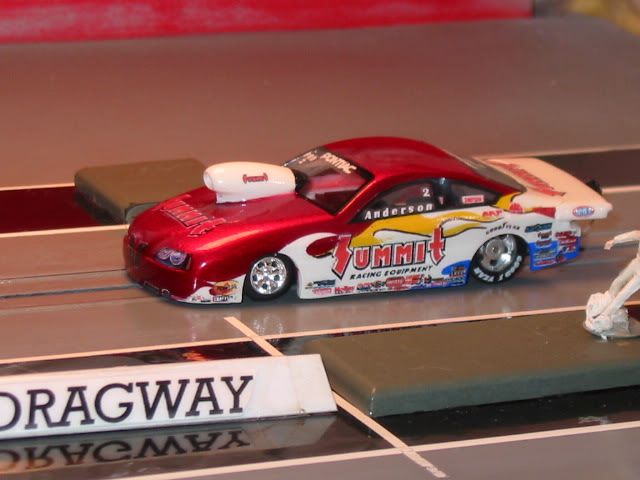

Hi Bob, glad you like the thread. The wheels are a tight fit and might require some trimming on the inside of the body. Let me know if you can't come up with anything that is going to work and I'lll send you out some really narrow silly foams. A buddy of mine and myself will be offering these up around the beginning of the year. The wheels are delrin and will have options of white, black and possibly chrome plated. Other options will be drilled holes and the Good Year lettering in white or yellow. They are made specifically for HO Drag RAcing where you really don't need a wide tire for some of the classes in racing. By Narrowing the wheels and lightening them up should translate into less rotating mass so in theory should get up to full RPM's quicker and possibly some additional RPM's. These ones here are 0.2 of a gram lighter per pair than the ones we were using. These are painted Chrome   |

|

ol55

Pro Stock

Posts: 117

|

Post by ol55 on Nov 30, 2010 11:54:00 GMT -7

SAM these tires and wheels interest me very much please let me know if these are something you are going to produce in the future. i would like to try some out. thanks ol55/johnny

|

|