|

|

Post by AJR on Jan 18, 2020 8:34:22 GMT -7

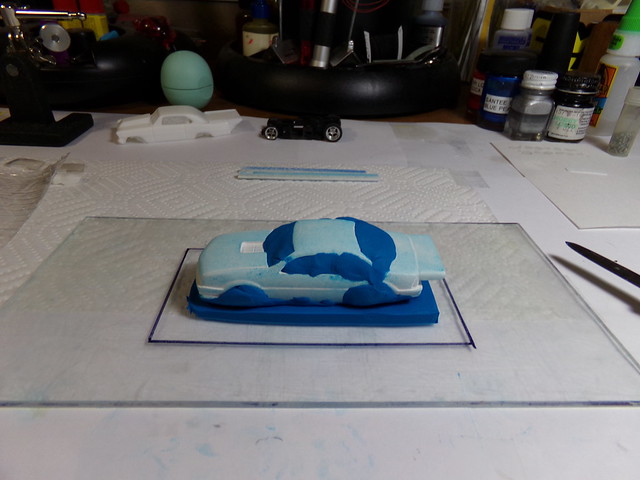

Another quick '94 Beretta project update. Things are moving along slowly but steady. Bodywork is almost completed. I still have some priming and blocking left to do to get everything straight. Mocking up a scoop for this car as well that will be cast with it. I do still need to fill in the gap in the bumper from the die cast wheelie bars. Wasn't sure what I was going to do there is why I waited till now. I will fill that in the same way that I extended the rocker panels...by putting tape over the outside and filling it in from the inside. Also working with the windows from the die cast version. Getting close to the mold making stage.

|

|

|

|

Post by AJR on Jan 18, 2020 8:38:51 GMT -7

This is the putty/body filler that I am using now and I really like it. I was using the Squadron green putty before this. It is good as well, but seemed to dry out quickly. The Tamiya does not do that near as bad and sands very easy. It also comes in different colors. Most of these putties can be diluted with acetone when they start to dry out....fyi.

|

|

|

|

Post by GTS on Jan 18, 2020 8:41:58 GMT -7

Wow! Really lookin' good!

|

|

|

|

Post by mazda on Jan 18, 2020 9:00:08 GMT -7

That is going to be one really good looking car. I can’t wait to see it completed.

|

|

|

|

Post by dave632 on Jan 18, 2020 18:57:21 GMT -7

Looks real good Jeff, that brings back some nice memories, going sideways at 100+ does not count however. |

|

|

|

Post by AJR on Feb 1, 2020 16:34:59 GMT -7

The body and accessories are ready for the mold making stage. I do need to block it one last time, but that's it. It will come with a scoop, blower hat, and of course windows. The builder will have a choice of what they want to use. These pictures are not much different than the last ones posted. But body mounts have been added, the die cast wheelie bar opening has been filled in, and parachutes added. Those will all be molded on the body. As I said prior....I am going to post the mold making process and then the casting process on this one for those that are interested.

|

|

|

|

Post by GTS on Feb 1, 2020 16:48:59 GMT -7

Definitely interested  |

|

|

|

Post by hairycanary on Feb 2, 2020 9:33:07 GMT -7

Jeff you did a awesome job on a body that needed a lot of work. Can’t wait to see it all painted up. Rick |

|

|

|

Post by hilltopspeedway on Feb 2, 2020 16:44:19 GMT -7

That's a gooooooooood looking body...put me on the list...RM

|

|

|

|

Post by AJR on Feb 2, 2020 17:39:27 GMT -7

Thank you guys for the good words!

|

|

|

|

Post by GTS on Feb 2, 2020 18:41:37 GMT -7

I'd like to get on that list, too.  I'd like to buy 1 or 2 when available, please. |

|

|

|

Post by AJR on Feb 4, 2020 16:35:36 GMT -7

I have finally reached the mold making stage with the '94 Beretta body. The next series of pictures is the claying up process of the body for the first half of the two part mold. There are many ways to do things....this is how I do it currently.

I use a plexiglass base and mini lego blocks for my mold. I've seen them used and I had a bunch on hand. They work fine, but there are better and more formal materials out there. I tend to use things that I have.

This is the casting clay that I use. It came in my first beginners casting kit I got from Micro Mark several years ago and I've been using it ever since. It can be used over and over.

I first create a base about 1/8" to 1/4" thick by rolling it out like dough. The black rectangle is the inside of the mold and where the car will be centered.

I fill the void on the inside of the body with the clay. I want to fill everything. The mold material will find it's way into anything that is not filled up and ruin the mold and waste material. I put my mold material in a vacuum chamber before pouring and then in a pressure pot at 60psi while curing.

I put the clay filled body on the base and trim the excess around the car. Leaving enough clay to mold the body to the base.

Body molded to the base by just pushing the clay up. I want more than I need because the excess will get trimmed away. Once again there cannot be any gaps or voids.

I start trimming away the excess clay a little at a time. I leave enough on the base to have the mold opening a little wider than the car for ease of casting removal. I also undercut my window openings and body edges so that the casting flash is on the inside edge rather than the outside. I trim by scraping the clay away with a tool. Then I use Q tips to smooth it out.

I finally take a Q tip and clean all of the excess clay and residue off the body. The mold material will pick up EVERY detail! Any errors, left clay, or other imperfections will live forever in the castings. That tool is a steak knife that has been ground down to it's current state in the picture  . I have some other formal claying tools, but I use this more than anything. The body is now ready for the first mold half. . I have some other formal claying tools, but I use this more than anything. The body is now ready for the first mold half.

|

|

|

|

Post by GTS on Feb 4, 2020 18:59:15 GMT -7

Intense!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Feb 4, 2020 20:13:46 GMT -7

good tutorial.

I too like Legos

|

|

|

|

Post by Eagle Racing on Feb 5, 2020 4:47:15 GMT -7

Nice tutorial Jeff, I like the body. What do you put on the Qtip to smooth clay and clean body?

|

|