|

|

Post by AJR on Jan 2, 2021 17:44:38 GMT -7

That's cool!!

|

|

|

|

Post by hairycanary on Apr 21, 2021 22:19:33 GMT -7

I casted up some new bodies a couple of weeks ago and have been doing a couple of modifications to the wheel base to fit different chassis. I copied the Mega G+ 69 Mustang. This is how I modify the wheel bases. Tried many different ways and this way has worked best for me because I screw up so much that its easy to fix.  Untitled Untitled by rick williamson, on Flickr Sitting on a Super G+ chassis  Untitled Untitled by rick williamson, on Flickr I ground out the fender wheels to fit chassis  Untitled Untitled by rick williamson, on Flickr Then I ground out the inside around the wheel wells and rocker panel and where ever else putty will be added so the putty I'm going to add will blend in with the body.  Untitled Untitled by rick williamson, on Flick Ran some masking tape along the whole side of car  Untitled Untitled by rick williamson, on Flickr Mixed up some of this finishing putty. Love this stuff. Mix as much as you need at a time and you can sand and prime in 15 minutes. The bag on the right is new style container and is easier to use and a little cheaper than the old style container on the left. The bag is around $35 and will last a long time. Got it on Amazon.  Untitled Untitled by rick williamson, on Flickr It will stay good for over night on your palette. Like I said you can squeeze out as little as you want.  Untitled Untitled by rick williamson, on Flickr Spread it on the inside side to cover wheel wheels and I'm adding some to the rocker panel too.  Untitled Untitled by rick williamson, on Flickr After the tape is removed about 15 minutes or sooner.  Untitled Untitled by rick williamson, on Flickr After grinding out wheel wells and trimming rocker panel. Then more sanding and filling until you get it to where you want it.  Untitled Untitled by rick williamson, on Flickr Before and after. It still needs finishing but you get the idea. You can screw up until you run out of putty and I've come close   Untitled Untitled by rick williamson, on Flickr This is a Mega G+ Camaro I'm working too to fit a 4G. The wheelbase is good just ugly wheel wells. |

|

|

|

Post by hairycanary on Apr 21, 2021 22:41:42 GMT -7

Found this short video thought I would share it. This was at Boise in 2019 the last year we ran the car. Think this was a Friday evening qualifying session. I'm in the right lane our nemesis in the left lane. They had a small explosion. The commentary is the car owner recording from the tow vehicle. Track has a very narrow groove. Saturday night session we broke the crank at around the 1200 foot mark. Could have been all bad. Think we lost 2nd round on Sunday.

Untitled Untitled by rick williamson, on Flickr |

|

|

|

Post by AJR on Apr 22, 2021 8:27:28 GMT -7

Found this short video thought I would share it. This was at Boise in 2019 the last year we ran the car. Think this was a Friday evening qualifying session. I'm in the right lane our nemesis in the left lane. They had a small explosion. The commentary is the car owner recording from the tow vehicle. Track has a very narrow groove. Saturday night session we broke the crank at around the 1200 foot mark. Could have been all bad. Think we lost 2nd round on Sunday.

Untitled Untitled by rick williamson, on Flickr

Thank you for the tutorial / tips above! I use the same or very similar method for redoing the wheel wells, but I use JB Weld. I have never used the Metal Glaze product. I need to look into that. |

|

|

|

Post by hairycanary on Apr 22, 2021 9:39:09 GMT -7

Found this short video thought I would share it. This was at Boise in 2019 the last year we ran the car. Think this was a Friday evening qualifying session. I'm in the right lane our nemesis in the left lane. They had a small explosion. The commentary is the car owner recording from the tow vehicle. Track has a very narrow groove. Saturday night session we broke the crank at around the 1200 foot mark. Could have been all bad. Think we lost 2nd round on Sunday.

Untitled Untitled by rick williamson, on Flickr

Thank you for the tutorial / tips above! I use the same or very similar method for redoing the wheel wells, but I use JB Weld. I have never used the Metal Glaze product. I need to look into that. Thanks Jeff !! I made it un private ? Never posted a video through Flickr. Hope it works now ? |

|

|

|

Post by pete on Apr 22, 2021 15:17:25 GMT -7

Way cool Rick. Looks like all 8 lit up, little move over but you stayed in it, Freaken Awesome! It looks like a nice night.

Thank you for sharing this.

|

|

|

|

Post by GTS on Apr 22, 2021 17:03:03 GMT -7

Awesome video, love it! (I had to click on it twice to view, for some reason)

Love the "how to" on the wheel wells! I'm thinkin' that technique could be used on some other body situations. Great stuff, thanks for sharing!

|

|

|

|

Post by kiwidave on Apr 22, 2021 19:28:08 GMT -7

Awesome stuff Rick.

|

|

|

|

Post by ecbill on Apr 23, 2021 7:51:56 GMT -7

I casted up some new bodies a couple of weeks ago and have been doing a couple of modifications to the wheel base to fit different chassis. I copied the Mega G+ 69 Mustang. This is how I modify the wheel bases. Tried many different ways and this way has worked best for me because I screw up so much that its easy to fix.  Untitled Untitled by rick williamson, on Flickr Sitting on a Super G+ chassis  Untitled Untitled by rick williamson, on Flickr I ground out the fender wheels to fit chassis  Untitled Untitled by rick williamson, on Flickr Then I ground out the inside around the wheel wells and rocker panel and where ever else putty will be added so the putty I'm going to add will blend in with the body.  Untitled Untitled by rick williamson, on Flick Ran some masking tape along the whole side of car  Untitled Untitled by rick williamson, on Flickr Mixed up some of this finishing putty. Love this stuff. Mix as much as you need at a time and you can sand and prime in 15 minutes. The bag on the right is new style container and is easier to use and a little cheaper than the old style container on the left. The bag is around $35 and will last a long time. Got it on Amazon.  Untitled Untitled by rick williamson, on Flickr It will stay good for over night on your palette. Like I said you can squeeze out as little as you want.  Untitled Untitled by rick williamson, on Flickr Spread it on the inside side to cover wheel wheels and I'm adding some to the rocker panel too.  Untitled Untitled by rick williamson, on Flickr After the tape is removed about 15 minutes or sooner.  Untitled Untitled by rick williamson, on Flickr After grinding out wheel wells and trimming rocker panel. Then more sanding and filling until you get it to where you want it.  Untitled Untitled by rick williamson, on Flickr Before and after. It still needs finishing but you get the idea. You can screw up until you run out of putty and I've come close   Untitled Untitled by rick williamson, on Flickr This is a Mega G+ Camaro I'm working too to fit a 4G. The wheelbase is good just ugly wheel wells. Rick, That's a fantastic idea. Thank you for sharing the process. I have a few bodies that have the wheel wells hogged out for monster truck tires. Been trying to figure out a way to fill them in successfully. How durable are the filler pieces once complete? Wondering if it would hold up after a few hits off the wall. Thanks, Bill |

|

|

|

Post by hilltopspeedway on Apr 23, 2021 8:53:08 GMT -7

Good stuff Rick...!!! Glad to see ya back casting...thanks for the pics and how-to's....RM

|

|

|

|

Post by dave632 on Apr 23, 2021 13:50:10 GMT -7

Found this short video thought I would share it. This was at Boise in 2019 the last year we ran the car. Think this was a Friday evening qualifying session. I'm in the right lane our nemesis in the left lane. They had a small explosion. The commentary is the car owner recording from the tow vehicle. Track has a very narrow groove. Saturday night session we broke the crank at around the 1200 foot mark. Could have been all bad. Think we lost 2nd round on Sunday.

Untitled Untitled by rick williamson, on Flickr Nice video. Sure remember those days well. |

|

|

|

Post by hairycanary on Apr 23, 2021 23:14:33 GMT -7

Bill I thought of you when I did this How To. I remember you asking the question on the wheel wells. I didn't have no pictures to explain it at the time. I think it would survive some guardrail shots to a point ? This stuff is real tuff and durable. The key is to grind the body at a taper far enough so you have 1/2 putty and 1/2 body if that makes sense ? If you grind it to thin on your finish grind when your all done and ready for paint it will crack. If your final thickness is the same as a standard body or just a tad thicker I think you'll be good ? I very rarely have them crack while molding them for casting. They go through some heavy stress through the process sometimes. I've tried bondo and other similar fillers and this stuff is by far superior in all areas. Easy to sand it feathers nice it dries fast it's really thin and spreads nice. I use it to widen some bodies to. This is a Cougar FC I started years back. Its among a crap load of other bodies that I need to finished   3B959597-124E-486D-B01F-65C6BC552D01 3B959597-124E-486D-B01F-65C6BC552D01 by rick williamson, on Flickr |

|

|

|

Post by ecbill on Apr 24, 2021 6:26:22 GMT -7

Bill I thought of you when I did this How To. I remember you asking the question on the wheel wells. I didn't have no pictures to explain it at the time. I think it would survive some guardrail shots to a point ? This stuff is real tuff and durable. The key is to grind the body at a taper far enough so you have 1/2 putty and 1/2 body if that makes sense ? If you grind it to thin on your finish grind when your all done and ready for paint it will crack. If your final thickness is the same as a standard body or just a tad thicker I think you'll be good ? I very rarely have them crack while molding them for casting. They go through some heavy stress through the process sometimes. I've tried bondo and other similar fillers and this stuff is by far superior in all areas. Easy to sand it feathers nice it dries fast it's really thin and spreads nice. I use it to widen some bodies to. This is a Cougar FC I started years back. Its among a crap load of other bodies that I need to finished   3B959597-124E-486D-B01F-65C6BC552D01 3B959597-124E-486D-B01F-65C6BC552D01 by rick williamson, on Flickr Thanks again for sharing your techniques! Its really cool how you widened the Cougar but the hood fang doesn't look out of proportion with the rest of the body. Looking forward to seeing that Cougar when its done! It sounds like you use this filler mostly to modify bodies, to use for making new molds. We used to use that filler when doing body work on full size cars. It is nice to work with. |

|

|

|

Post by ecbill on Apr 26, 2021 7:15:13 GMT -7

Bill I thought of you when I did this How To. I remember you asking the question on the wheel wells. I didn't have no pictures to explain it at the time. I think it would survive some guardrail shots to a point ? This stuff is real tuff and durable. The key is to grind the body at a taper far enough so you have 1/2 putty and 1/2 body if that makes sense ? If you grind it to thin on your finish grind when your all done and ready for paint it will crack. If your final thickness is the same as a standard body or just a tad thicker I think you'll be good ? I very rarely have them crack while molding them for casting. They go through some heavy stress through the process sometimes. I've tried bondo and other similar fillers and this stuff is by far superior in all areas. Easy to sand it feathers nice it dries fast it's really thin and spreads nice. I use it to widen some bodies to. This is a Cougar FC I started years back. Its among a crap load of other bodies that I need to finished   3B959597-124E-486D-B01F-65C6BC552D01 3B959597-124E-486D-B01F-65C6BC552D01 by rick williamson, on Flickr It took a while to recall my question about wheel wells. You are referring to the post with the red 68 Mustang, sizzler Cuda and 52 Chevy truck bodies, who’s wheel wells didn’t quite line up with the available chassis options. Your idea would probably work great, since you could grind out the openings wherever works best. Thanks! |

|

|

|

Post by hairycanary on May 2, 2021 22:23:56 GMT -7

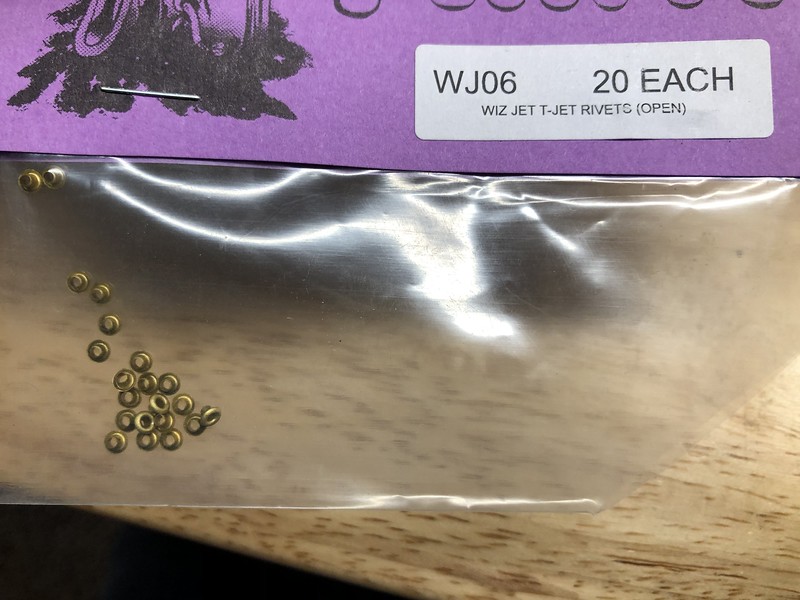

I didn't get a chance to try Robert shunt idea yet and Jeff what you did with it came out really good and can't wait to try it. After Al posted his ideas this is what I did as a quickie with stuff I had on hand. I put the hotter 2.5 arm back in My 4G unlimited that was over heating the brush springs. Jeff the brushes and everything was good in it when I got it back from your race. I took it apart put it back together with all the same parts even the brushs and springs and it ran on my track what it did in testing before your race. So I don't know what happened besides put on a good show  Anyway this what I did. I took a Wizzard Tjet rivet and soldered the shunt to it and filed it down flat on top and bottom not to bottom out. I didn't insulate it and just ran it straight to the shoes. It didn't perform as well as I well I thought it should have .540 @ only 27mph I made 15 runs without the springs failing and no noticeable heat. Those runs was all made at 26 volts.  Untitled Untitled by rick williamson, on Flickr  Untitled Untitled by rick williamson, on Flickr  Untitled Untitled by rick williamson, on Flickr I think with a little more testing, try to insulate the shunt and some fine tuning they might work OK ? Going to give Roberts a try next. Rick |

|