|

|

Post by AJR on Feb 2, 2013 11:01:02 GMT -7

Yes sir Sam.......Now this is the kind of stuff I want to see. I'm still relatively new to this. The ball bearings....magnets....right on!!! I am watching close. Good stuff.

Jeff

|

|

|

|

Post by chriswfo on Feb 2, 2013 11:03:38 GMT -7

PC, I'm not ready to wind my own arms yet, I'm going to offset the brush cups to advance the timing.

Sam, I'm looking forward to see how your magnet set up works, I don't like the slop in the rear axle of the 4 gear chassis and was planning on using bushings there instead of the more expensive bearings, along with the Tyco axle and a larger crown gear.

|

|

|

|

Post by SKR on Feb 2, 2013 11:10:45 GMT -7

yeah, I'm not a fan of the slop. Can't beat the price for these bearings 10 for $7 free shipping on ebay. Takes a few weeks for delivery. Link is posted under my pictures on page 2.

|

|

|

|

Post by chriswfo on Feb 2, 2013 12:03:31 GMT -7

Sam, those a lot cheaper then what I've seen. Bearings it is. Bet these would work in the gear plate too.

|

|

|

|

Post by Eagle Racing on Feb 2, 2013 12:05:55 GMT -7

Looking good Sam. I am looking forward to seeing the improvements in action. The FED races or going to be a lot of fun.

|

|

|

|

Post by nosubfor3 on Feb 3, 2013 10:29:47 GMT -7

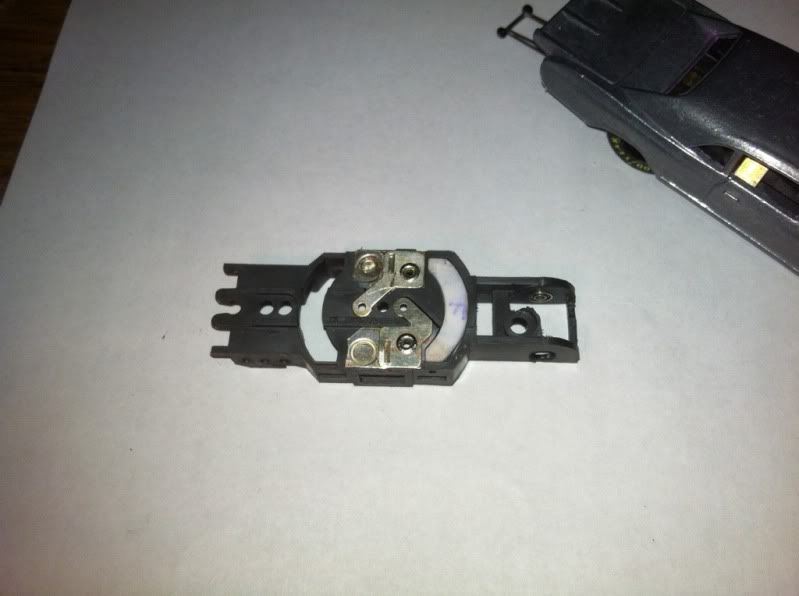

Here is an update on my build. Picked up some Neo Dots from KJ Magnetics that are 2 times as strong as the rare earth mags from Radio Shack. I'll still be playing around with the Quad set up. I made my magnet set up into somewhat of a quick change for tuning by cutting out the bottom part of the chassis that holds the mags in and drilling holes into the side of the chassis so I could use straight pins to hold the resin blanks in place. This way I can pull them out from the bottom without pulling the chasssis clip and screw.   I'll also be running ball bearings. These bearings are perfect for running .059" (Tyco Size) axles.  You can buy them here: www.ebay.com/itm/290749723278?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649 WHAT SIZE DRILL DO YOU USETO DRILL OUT THE CHASSIS FOR THE BEARINGS TO FIT? |

|

|

|

Post by SKR on Feb 3, 2013 11:06:12 GMT -7

5/32"

|

|

|

|

Post by pceng on Feb 5, 2013 12:41:17 GMT -7

Took traction magnet out (mentioned under smack) and put right back after 2 passes. Way to much wheel spin with only one t/mag. .300w silicon on Wizard hubs, about .510d any bigger won't stay on track.

......... PC

|

|

|

|

Post by chriswfo on Feb 9, 2013 13:23:54 GMT -7

Sam, Just wondering if you lowered the rear axle location when installing the bearings to allow for a larger crown gear.

|

|

|

|

Post by SKR on Feb 9, 2013 16:07:17 GMT -7

No I haven't but I like the thinking. Lots of possibilties in this class.

|

|

|

|

Post by chriswfo on Feb 9, 2013 18:23:22 GMT -7

That's what interests me about it. With a good start to the season in Sportsman and Combined I was going to concentrate on those classes but the experimentation is too much to resist here. Bearings are on the way, going to order an arm very quickly from one of our sponsors here. Scrapping the stock electrical system and making some adjustments to the timing. I am going to make the timing adjustable so I can experiment with the settings. Considering a way to make axle height adjustable for gear changes. Going to need to do a gearing spreadsheet to get an idea of how much changing the crown gear affects the overall ratio. Anybody have a way to measure the rpm accurately?

|

|

|

|

Post by Eagle Racing on Feb 10, 2013 5:32:01 GMT -7

chriswfo: (Anybody have a way to measure the rpm accurately?) Yep, I use a laser tach can be purchased on ebay.

|

|

|

|

Post by pceng on Feb 13, 2013 12:39:59 GMT -7

Body got painted before rain started today. If things dry up might get some testing on tire size done, braids changed everything. Some experimenting with t/mag also needed. Don't want to use wheelie-bars.

|

|

|

|

Post by chriswfo on Feb 14, 2013 8:44:04 GMT -7

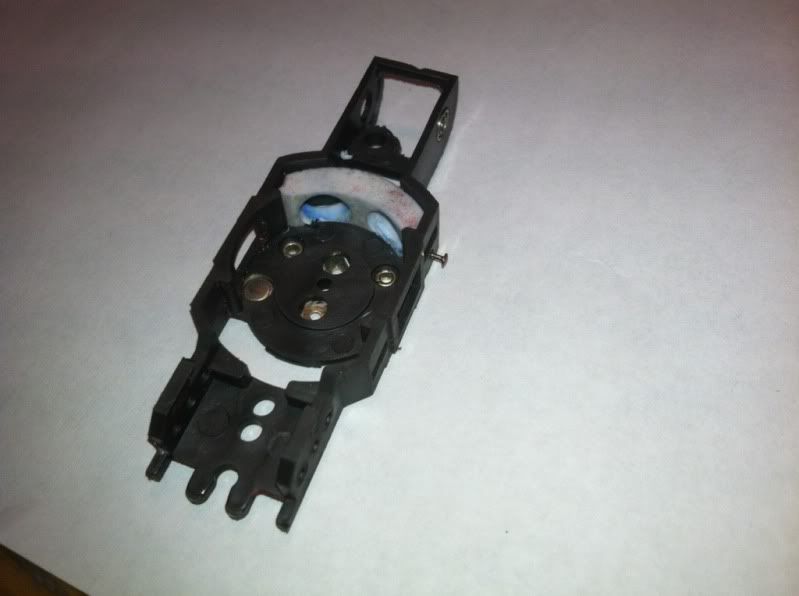

I have found that whenever you try to drill an offset hole it will not go right if you try to do it freehand. As I do not have a drill press available (or any other machine tools), I came up with these two drilling fixtures. One is to drill the holes for the brush cups offset with 15 degrees advance and 180 degrees from each other and the other is to drill the holes for the ball bearings at the rear of a 4 Gear chassis. I am lowering the axle centerline about 1/32 to allow for the larger crown gear. Biggest thing here was to make sure the holes are lined up. I decided to go with the offset brushes rather then an advanced arm as I can swap any arm in and still have the extra power from the advanced timing. I know these hot arms have a short life so I can throw in a mean green or something if I burn one up. This also allows me to maybe try winding some motors of my own later and using the stock commutator. |

|

|

|

Post by Phantom B.S.E. on Feb 14, 2013 11:15:55 GMT -7

Does anyone know where I can get a F.E.D. body?

|

|