|

|

Post by hilltopspeedway on Feb 9, 2018 13:28:05 GMT -7

Got to get a set of those pretty wheels...!!! RM

|

|

|

|

Post by onefastmustang on Feb 9, 2018 17:39:49 GMT -7

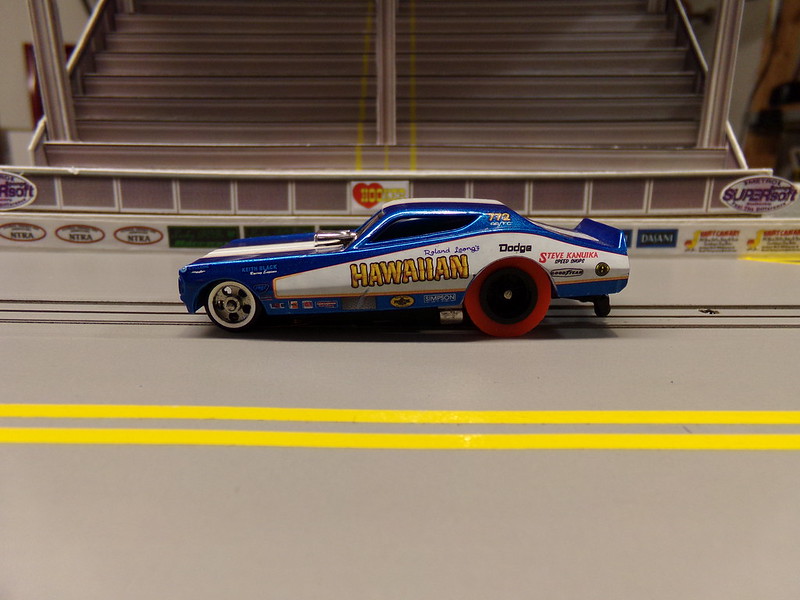

That’s sweet looking ride and love the wheels

|

|

|

|

Post by AJR on Feb 11, 2018 16:43:49 GMT -7

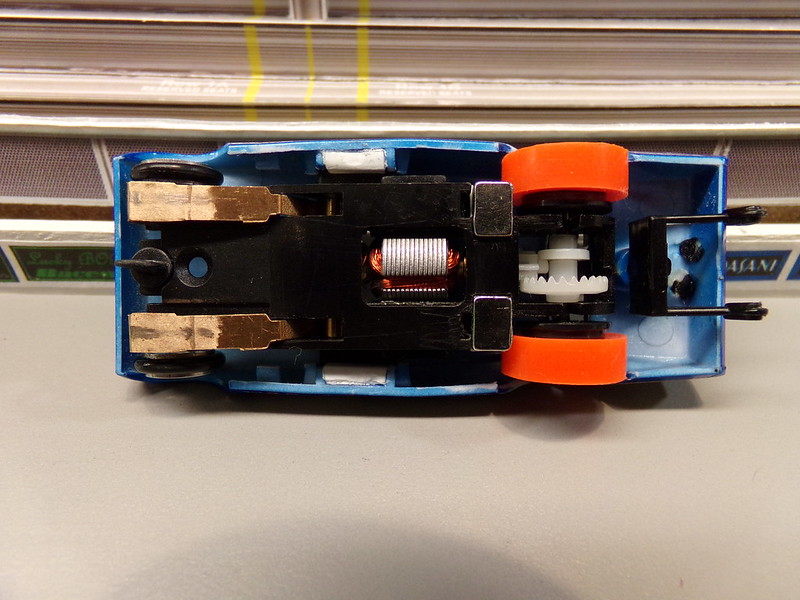

OK this is probably the last post for my tuning on the stock DR-1. The only parts that I've added are the front wheels and rear tires.....only minor material removal around traction magnets and narrowed the rear rims. Car is totally stock beyond that. I have done two things since my last post. First I flattened the "step" on the pick up shoes. The idea was to increase the contact patch. In doing that it changed the geometry of the shoe to the spring. So I had to stretch them slightly. Second I added a bigger rear tire. I was running a .540dia tire....the orange tire is .560dia. I normally only run a black tire, but that is all I had that would give me that size. The car initially slowed way down till I got everything tuned for the new changes. Mostly pick up shoes and springs. Did not need to adjust traction magnet since they are plenty strong. Last three runs .5749, .5791, .5785. I have to leave it alone at some point....I think this is it.  I ordered another chassis to do some tweaking on. This is fast becoming one of my favorite cars!   These two pics show the trac mag mods, narrowed and tucked wheels, and also the flattened pick up shoes.  This body seems to fit the chassis very well. It sits as low as I can get it. The front is very shallow and the wheels are right on the hood. I am anxious to see what others can do with the stock version. .57et seems pretty quick, but I am comparing to nothing........it could be slow?  |

|

|

|

Post by dave632 on Feb 12, 2018 9:22:13 GMT -7

Looks like you are the official stock champ for right now Jeff. I have not tried any of the chassis without braid outside of when they first ran out of the box. Your car is almost .2 faster than any of those. Nice going. I also like this chassis and will include them in my April race.

|

|

|

|

Post by AJR on Feb 12, 2018 16:36:00 GMT -7

Thanks Dave. I look forward to seeing what others can do with it as well. I wanted to see what it could do and it did not disappoint.

|

|

|

|

Post by nosubfor3 on Apr 1, 2018 15:29:26 GMT -7

Has any one tried to narrow the stock wheels to tuck under lowered body's? This chassis should definitely be in our line up of inline classes.

|

|

|

|

Post by dave632 on Apr 1, 2018 17:28:30 GMT -7

The chassis is allowed in all the classes at the upcoming Smoky mountain race.

|

|

|

|

Post by AJR on Apr 2, 2018 3:28:06 GMT -7

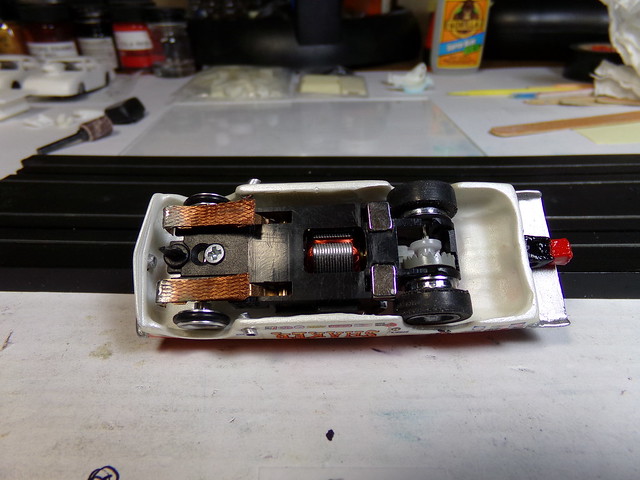

Has any one tried to narrow the stock wheels to tuck under lowered body's? This chassis should definitely be in our line up of inline classes. Vince my Charger that is above your post on the same page has been narrowed and much larger tires added. They tucked in nicely. Also this is my other DR-1 chassis I'm working on for the race. I am putting the Shaker Vega body on it....much narrower, but it's works. The tire that is on it is just a test tire and is larger than the stock .510. The DR-1 rims are 100 times better than the 4 gear rims (rears)!!

|

|

|

|

Post by dave632 on Apr 2, 2018 9:46:17 GMT -7

Nice work, did you have to cut those tires/rims down manually?

|

|

|

|

Post by AJR on Apr 2, 2018 14:12:31 GMT -7

Yes Dave I did. I've tried several ways of cutting down the rims and have settled on one method that seems to work the best. I use a pull saw and miter box for the wheels and a Dremel for the tires. I should probably do a tutorial....I don't know that there is one on the forum for that. I know some people use a Dremel for the wheels too, but for me it would cut too fast and increase the chance messing it up. Also it can generate too much heat and start melting the wheel. I don't like to sand the face of the rim either because it just doesn't look right (can't do it on chrome for obvious reasons) and I leave a little of the flange on the back. I could probably go ahead and cut the flange all the way off and give the wheel plenty of room. As you can see in the pictures the flange isn't even used because the tires are much more narrow so as not to not ride on the power rails. I will work on doing some kind of tutorial if there is some interest.

|

|

|

|

Post by dave632 on Apr 2, 2018 17:18:44 GMT -7

We need to start some kind of tutorial thread that all can find since the site took all of it away.

|

|

|

|

Post by GTS on Apr 2, 2018 17:59:50 GMT -7

Yes Dave I did. I've tried several ways of cutting down the rims and have settled on one method that seems to work the best. I use a pull saw and miter box for the wheels and a Dremel for the tires. I should probably do a tutorial....I don't know that there is one on the forum for that. I know some people use a Dremel for the wheels too, but for me it would cut too fast and increase the chance messing it up. Also it can generate too much heat and start melting the wheel. I don't like to sand the face of the rim either because it just doesn't look right (can't do it on chrome for obvious reasons) and I leave a little of the flange on the back. I could probably go ahead and cut the flange all the way off and give the wheel plenty of room. As you can see in the pictures the flange isn't even used because the tires are much more narrow so as not to not ride on the power rails. I will work on doing some kind of tutorial if there is some interest. A tutorial on this procedure definitely has my vote! And, I know it's a busy time for you and others but I will be looking forward to it when time allows. |

|

|

|

Post by onefastmustang on Apr 6, 2018 14:46:37 GMT -7

That Vega body is sitting nicely on that chassis, great job

|

|

|

|

Post by sandfly on Apr 9, 2018 17:19:58 GMT -7

Greetings fellow racers, FYI. I purchased 2 of these chassis and spent a bit of time changing the crown gear ratio and pinon gear ratios to see what worked also played with smaller rim and tyre sizes, the issue is the rear part of the chassis were the axle clicks in is very very loose to the point the car is no longer usable as it crabs sideways down the track, so I got the other new one out and checked the rear end, seemed ok, I then oiled this car and ran it in on the dyno the other car was not run on the dyno, also did a bit of gear lapping as I went, I started at 8.5 volts and up to 15 volts, tried once at 18 volts but threw the rear tyres off. this car has done about 40-50 mins on the dyno over the course of an afternoon, this car is now showing signs of excess wear in the rear chassis, has any one else found this. Am going to fix it by adding brass sleeves to the axle as I have one on aw tjets.

|

|

|

|

Post by dave632 on Apr 9, 2018 17:24:00 GMT -7

I have not had the problem but I have not run the chassis 40-50 min. I would also check the axle size as I believe they use .063 not .059 on these chassis.

|

|