|

|

Post by Eagle Racing on Jan 2, 2021 6:52:33 GMT -7

Rick, nice setup and the gear looks great.

|

|

|

|

Post by GTS on Jan 2, 2021 9:20:09 GMT -7

Simply in awe . . . .

|

|

|

|

Post by dave632 on Jan 2, 2021 10:37:52 GMT -7

Nice work Rick those are looking great.

Where did you find a Mini Lathe for 100.00??

The ones I have seen were about 550.00.

|

|

|

|

Post by AJR on Jan 2, 2021 17:53:03 GMT -7

WOW!!

|

|

|

|

Post by hairycanary on Jan 2, 2021 22:55:27 GMT -7

Nice work Rick those are looking great. Where did you find a Mini Lathe for 100.00?? The ones I have seen were about 550.00. Dave the lathe I got used for $100 but it works pretty good. The Mill a buddy gave me. It’s pretty big but gets the job done. I have a larger older lathe that needs work that I’m slowly fixing up also. Just need to learn how to use them😁 Rick |

|

|

|

Post by ecbill on Jan 3, 2021 11:13:10 GMT -7

Nice job Rick, what are you using to cut and measure the teeth? Dave to answer your question here is how I'm doing it so far in my Okie Machine Shop   Untitled Untitled by rick williamson, on Flickr  Untitled Untitled by rick williamson, on Flickr This is my $100 mini lathe I use to turn the rod down and hog out the center area.  Untitled Untitled by rick williamson, on Flickr This is the dividing head I got off ebay that if you do the math right it will cut the teeth evenly spaced.  Untitled Untitled by rick williamson, on Flickr This is the 60 degree double cutter that I found because I couldn't find a 60 pitch gear cutting set anywhere. I have a metric gear cutting set ordered from China but don't know if it's going to be small enough ?  Untitled Untitled by rick williamson, on Flickr Then I put it back in the lathe to cut the back side.  Untitled Untitled by rick williamson, on Flickr  Untitled Untitled by rick williamson, on Flickr These are the measurements I come up with so far. I'm trying to keep it around .090 thick which gives you room to shim, and around .320 diameter and maybe see if I can go a little bigger later ? If I don't GOOF it takes about a hour from start to finish. There about .003 to .006 out of round because of my lathe, but the little testing I've done seems to be ok ? More testing is needed. Rick, This stuff is pretty fascinating. You mention a dividing head, and the cutter you are using looks like its divided into segments. Does it rotate in a vertical axis while the blank rotates in the horizontal axis, cutting out the teeth with the appropriate spacing? Picturing it working kinda like the old fighter plane machine guns, that would fire through the rotating prop without shooting up the prop blades. Bill |

|

comet

Pro Stock

Posts: 363

|

Post by comet on Jan 4, 2021 18:31:09 GMT -7

Nice mini laithe and a nice bridge port. awesome work on the gears.

|

|

|

|

Post by swiftkart on Jan 8, 2021 15:01:52 GMT -7

You sure look like a master machinist to me, those gears look great and the deeper the better.

|

|

|

|

Post by dave632 on Jan 11, 2021 8:26:42 GMT -7

Any metal gears we get would be welcome. If we finally get some we can then

judge how good they are. I only have one metal gear which I got from Eagle which is a

casting. Ricks gears look very good and I am looking forward to testing them.

|

|

|

|

Post by hairycanary on Feb 7, 2021 23:13:57 GMT -7

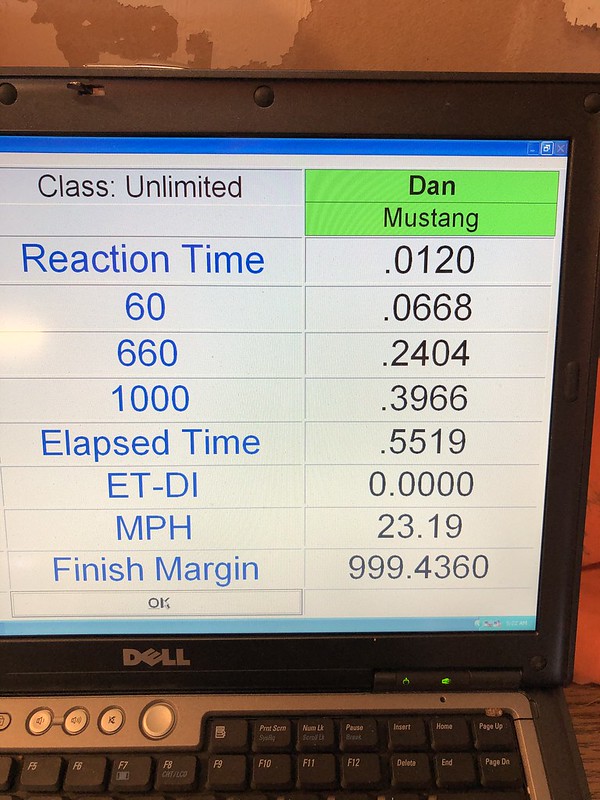

Had some time this morning to work on my 4G unlimited. I actually made progress for the first time. I made a brass Cluster gear. I tested in the chassis I had started with the 20T Wizzard gear. On that chassis I tried to stabilize the plastic cluster gear to make it live. But didn't work so I put it aside. The brass cluster seemed to work pretty good but still geared to low. I tested it with some .590 Eagle Sillyfoams that held up real good. I used a 4.5 ohm arm with poly mags, braids no shunts no wheelie bar. Basically threw a bunch of junk together to see if the brass cluster would work. To make the cluster gear I drilled out the center of the 20T gear so a Wizzard 12T fit and soldered them together. The picture shows how I stabilized the brass gear and so far is working pretty good. Went to my son's for dinner, Super Bowl and grand kids so I had to cut the testing short today. Now to start on one with good parts. Not going to scrap this one because most likely it will out preform the new one I build   DSC00059 DSC00059 by rick williamson, on Flickr  DSC00060 DSC00060 by rick williamson, on Flickr  Untitled Untitled by rick williamson, on Flickr  Untitled Untitled by rick williamson, on Flickr  Untitled Untitled by rick williamson, on Flickr This was the best that the 20T crown chassis ran at 26 volts.  Untitled Untitled by rick williamson, on Flickr This was with a 15T crown same top plate from the chassis used with the 20T. This chassis was a old wore out 4GO and the tires are .540 diameter on double flange wheels not glued and again no wheelie bar. This was at 24 volts and ran 10 runs consistently. Then I turned it up to 26 volts and ran a best of .510 @ 27 MPH. forgot to take a pic. Got a long way to go but for me it's start ? Hopefully this gives me a good base line to work with ? But like most everything I will most likely Goof it up   DSC00056 DSC00056 by rick williamson, on Flickr This is the latest 15T crown for a T-jet  DSC00057 DSC00057 by rick williamson, on Flickr Latest for the 4G |

|

|

|

Post by dave632 on Feb 8, 2021 5:50:10 GMT -7

Very clever work Rick.

|

|

|

|

Post by mazda on Feb 8, 2021 8:50:04 GMT -7

That is truly amazing the way you guys build these little monsters. I am in awe of the precision work that is done.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Feb 8, 2021 11:37:32 GMT -7

that is outside the box and will certainly set tongues a-wagging!

nice work Rick

|

|

|

|

Post by skillet on Mar 27, 2022 20:58:35 GMT -7

Coming soon....the "Head"  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 1, 2022 12:56:10 GMT -7

|

|